Aosa Seaweed Grown on Land – A New Way to Enjoy Aosa

Jul 17,2025

Aosa Seaweed Grown on Land – A New Way to Enjoy Aosa

Jul 17,2025

One day you may no longer be able to eat miso soup with aosa seaweed. Alarmed at that prospect, in 2017 Marukome launched a project to grow aosa seaweed (Monostroma nitidum) on land. The initiative bore fruit in September 2024 with the rollout of Nama Miso Soup Ryotei no Aji Aosa, a miso soup containing aosa seaweed grown onshore. To learn more, we talked with Matsushima Daijiro of Marukome’s Research & Development Division. He’s been working on the project in Seiyo, Ehime Prefecture, on the island of Shikoku, since it started.

The pilot land-based seaweed farm in Seiyo, Ehime Prefecture, overlooks the tranquil shores of the Inland Sea. Matsushima Daijiro welcomes us when he sees that we’ve arrived. Daijiro was chosen as a member of the team charged with setting up the inland seaweed farming project in his first year on the job. The first question we ask him: how did Marukome come to farm seaweed on land?

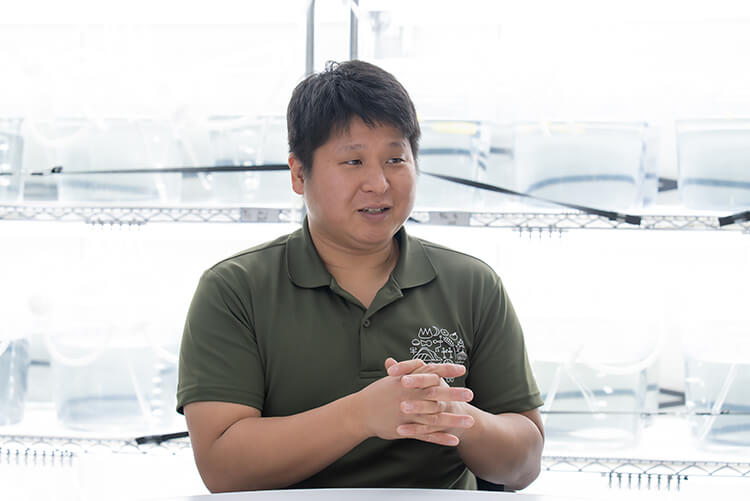

Matsushima Daijiro of Marukome’s Research & Development Division. He has studied botany and entomology at the undergraduate and graduate levels.

“Seaweed yields in Japan have been in decline over the years. In FY 2017, the year I joined Marukome, the price of seaweed jumped sharply. Miso soup with aosa seaweed was a popular item, and sales had been rising steadily. But that year we became increasingly concerned that one day, we would no longer be able to bring our customers products made with aosa seaweed. Then Dr. Yamamoto Hirofumi, professor of pharmaceutical science of the Tokushima Bunri University, succeeded in developing the world’s first technology for farming aosa seaweed on land. When we heard that news, we visited Professor Yamamoto, and that’s how the project got started.”

Soon the project was up and running. Daijiro sought technical advice from Professor Yamamoto, turning to him whenever he had questions or was in doubt.

In the project’s first year, Daijiro traveled all over Japan looking for a heat-tolerant strain of aosa seaweed while seeking a suitable site for a seaweed farm.

“Rising seawater temperatures are one of the reasons for falling aosa yields. Seaweed beds where aosa can be harvested are steadily shifting northward. I visited over forty coastal areas all over Japan in search of a strain of aosa seaweed that could withstand high water temperatures.”

Daijiro would collect samples at each stop and test them one by one. What was their maximum temperature tolerance? Were they suited to culturing indoors and growing outdoors? It was painstaking, repetitive work, but he finally discovered a strain that yielded the desired results. It was a great relief, he says.

“I figured that this particular strain might be heat-tolerant when I found it, so I kept my fingers crossed that it would be the one. When I realized for a fact that we could work with it, I wasn’t so much glad as relieved. Now we could finally take the next step.”

Daijiro next grew aosa seaweed for harvesting spores, which is called parent seaweed. He then selected and cultivated the strains that were most heat-tolerant. He repeated this process until he identified a strain that could be grown year-round.

Daijiro shows us around the facility so we can see for ourselves how aosa seaweed is grown.

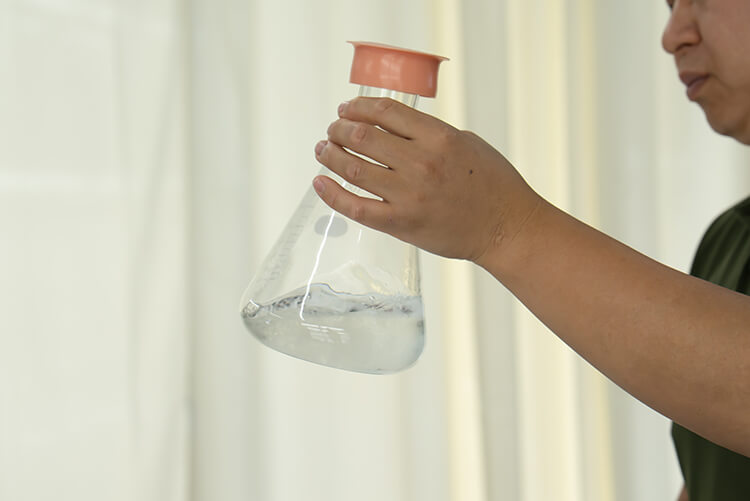

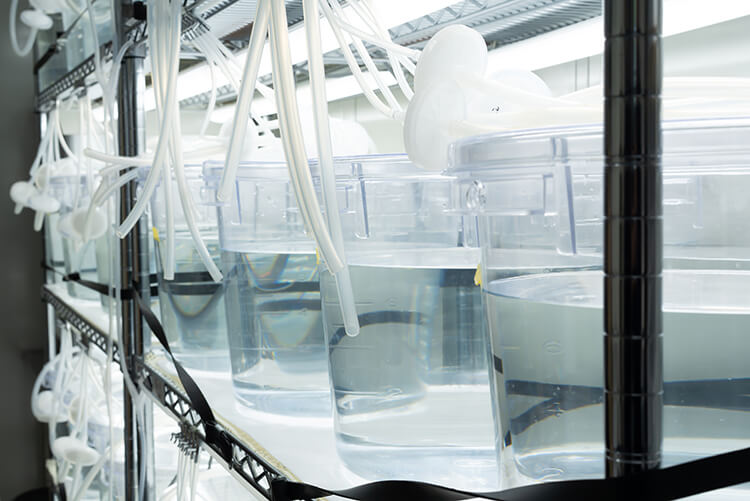

“This building is where the aosa parent seaweed is grown. The parent seaweed is so small at first that it can’t be seen with the human eye, but it turns green in about a week, after photosynthesis is triggered by supplying LED light and air to the container.”

It is indeed as Daijiro says. We compare containers at the initial stage, which appeared empty, with ones that are a week old. The latter contain something green that looks like baby aosa seaweed. There are other containers a further three weeks old, and seaweed can be seen growing inside. At this point, the seaweed is released into the tank outside.

“How efficiently the parent seaweed can be grown here affects the subsequent yield,” says Daijiro. “The process of growing the parent seaweed is the key to land-based seaweed farming.”

Parent seaweed being supplied with LED light and air

The containers initially look empty, but a green form becomes visible in about a week.

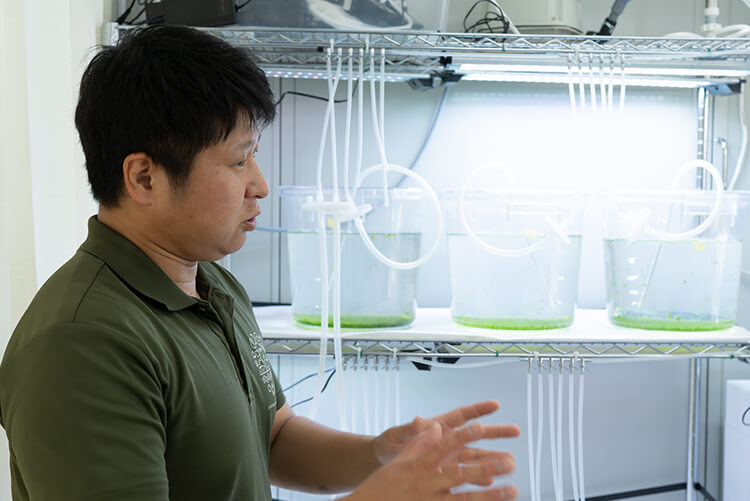

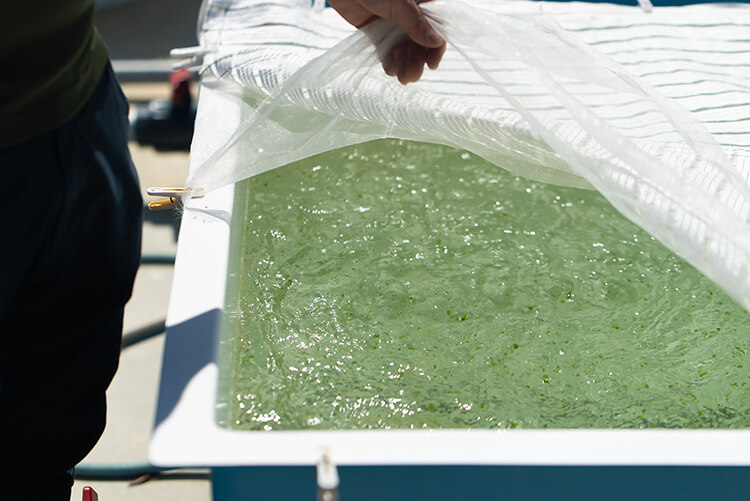

We step outside the building, and there are three sizes of tanks: 300 liters, five metric tons, and ten metric tons. We peek into the 300-liter tank. Still-tiny green aosa plants are being churned in the water.

Aosa seaweed in a 300-liter tank, having grown slightly larger than what we saw in the building

The water used at this pilot land-based seaweed farm is pumped from the nearby ocean.

“The pumped seawater is filtered before using. That lets us keep out unwanted objects like pieces of fishing line and shells. One of the advantages of farming seaweed on land is that it simplifies the process of inspecting for foreign objects compared with sea-based farming.”

Rain is allowed to fall into the tanks, says Daijiro, except when it’s torrential. “Rainwater contains nutrient salts. Also, rain causes nutrients from the land to leach into the sea. Rain is thus a blessing.”

The aosa seaweed grows luxuriantly in seawater from the nearby Inland Sea while exposed to the natural elements.

The aosa seaweed we saw in the building was tiny. As we examine the grown plants here, we ask Daijiro whether he feels an affection for them at this stage. “Yes, they’re like my own children,” he replies with a tender smile. “I’m glad when they thrive, and it makes me genuinely sad when they don’t. It’s the same emotion as primary producers like crop growers and livestock farmers have.”

Aosa seaweed starts out about the size of your fingertip; then it grows to the size of the palm of your hand as it’s transferred from the 300-liter tank to the five-ton and then the ten-ton tank. It’s then removed from the tank to be washed and dried.

On being removed from the tank, the aosa seaweed is a beautiful shade of green. A problem Daijiro faced at one point was that the color bleached out in the sun.

“We asked Professor Yamamoto for advice, and by taking a series of countermeasures, we found a way to keep the aosa a beautiful green, even when it’s put in miso soup. You can make aosa darker by adding nutrients to the seawater to deepen the color. But we’re not going to do that. We believe in working exclusively with what nature supplies and using natural seawater, and we resort to all kinds of tricks to achieve that.”

When Daijiro first ate aosa seaweed that he’d grown himself, he says that he got emotional because it looked so beautiful.

The moisture content is precisely adjusted during drying. The seaweed is then sent to the factory for processing.

After being dried, the seaweed is sent to the factory for processing.

Since September 2024, eight years after the project began, the aosa seaweed grown at this farm has reached consumers as one of the ingredients in Nama Miso Soup Ryotei no Aji Aosa.

“When our aosa seaweed was used in a product for the first time, I and the people I work with visited the factory in Nagano to watch it being shipped. That was a soul-stirring experience,” says Daijiro. He’d been involved in the project for eight years since joining Marukome fresh out of university. “I was relieved that, thanks to the support of Professor Yamamoto and many others, we’d finally reached the commercial production stage.” But that wasn’t the final goal. He has his sights set on the future.

“One day, we hope to supply enough land-farmed aosa seaweed for all our aosa products. To accomplish that, though, there’s still a lot we need to do, like boosting production volumes.”

Moreover, as yields of aosa seaweed and seaweeds in general slump, Daijiro has ambitions of leveraging the knowledge gained at the pilot farm for the greater good of the industry.

“The entire industry could end up going into decline if overall seaweed yields keep falling. As an industry leader, we want to explore various possibilities like finding sustainable ways to use other types of seaweed by applying land-based aquaculture technology. Above all, we’re going to continue working to safeguard Japan’s cherished culture of eating seaweed, so people everywhere can keep enjoying the great taste of miso soup with aosa seaweed.”

As Daijiro speaks, his face is filled with hope for the future and a determination to succeed.

Address: 1-696-4 Tawarazu, Akehama-cho, Seiyo-shi, Ehime Prefecture

To learn more, contact the Marukome Customer Service Center at 0120-85-5420.

Hours: 9:00 a.m.–5:00 p.m. Monday to Friday (excluding statutory holidays and the Bon and New Year’s holidays)